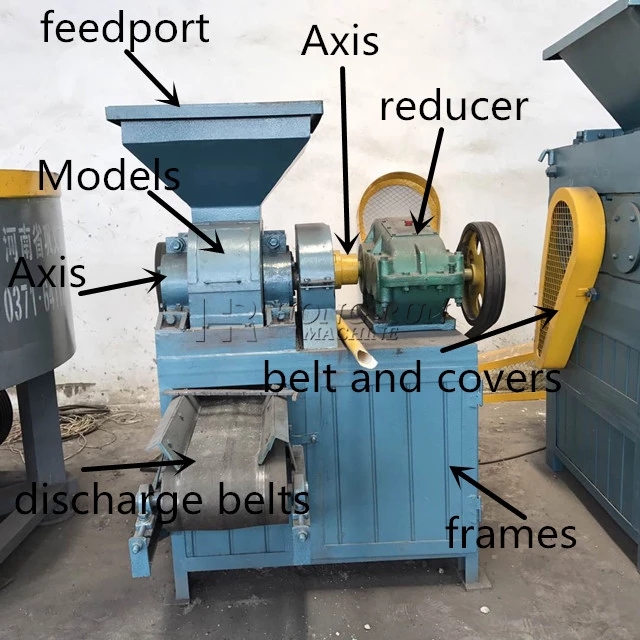

Hydraulic Dry Powder Balling Machine

This series of dry powder balling machine has a wide range of practical applications. It can produce various materials, such as lime powder, cryolite, alumina, chemical fertilizer, magnesium powder, bauxite, bauxite, bauxite and so on, and powder, accessories, refractory powder and high value-added materials in non-ferrous metal industry are more suitable for use. The purpose of ball pressing machine is to reduce dust pollution, control capacity, recycle waste and facilitate transportation. In steel mills, lime mills, metallurgy, refractory furnaces, magnesium mills, the use of calcined white powder balls is very extensive.

Dry powder balling machine is suitable for: white lime powder, metal magnesium powder, dust removal dust, aluminium ash powder and other materials that do not allow moisture content; wet powder balling machine should be used for materials that allow moisture content, because dry powder balling machine consumes more than wet powder balling machine, and the purchase cost is higher.

Working principle

The working principle of dry powder balling machine:

1. Pre-pressing stage: The material is pre-compressed first by the pre-press.

2. Pressure stage: the material to be pressed is forced into the middle of the roll to press (also known as re-exhaust) until it is fully molded to achieve maximum pressure.

3. Demoulding stage: After closing the mould, with the rotation of the pressing roll, the spherical cavity begins to separate continuously, which relieves the pressure on the ball. Under the centrifugal force of the roll speed and the pellet weight, the billet will be demoulded automatically.

4. In the production of ball pressing, the spherical edge material produced is normal, and the requirement is about 3mm.

5. According to the material, when the speed of roll and pre-pressing reaches the best match, all balls can be formed at one time. In practice, we should find out the best point accurately and remember it accurately.